THE ABF (ADVANCED BOUNDARY FILM) TECHNOLOGY

A Cutting Edge Technology – The Keystone of Steel Shield Product Line

During WWII, the German Science and Technology Research Institute was commissioned the mission of meeting the stringent demand for lubricants of heavy weapons such as armored vehicles, tanks and battleships to avail themselves of their maximum durability & performance with minimal maintenance. The concept of Magnetic Levitation was proposed to offset the mechanical deficiency. The maglev concept was first proposed during the start of the WWII, but it was not materialized until it came into the hands of Dr. George C Fennell.

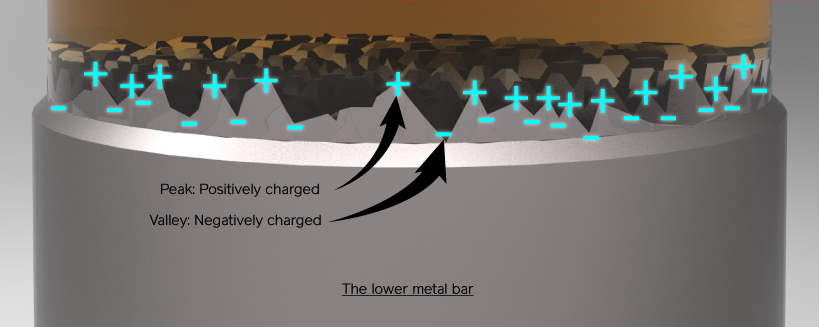

Shortly after the War, a large number of elite scientists from Europe migrated to the United States. Among them was an Irish scientist Dr. Fennell, who came with a large volume of research data about maglev. The old scientist continued his scientific research and eventually in 1986 a family member of his Dr. George C Fennell pursued a breakthrough and developed the ABF Technology. By treating the metal through the process of Electrochemical Ionization and caused a cation exchange the surface metal is elevated to a positive state of polarity. When all moving metal surfaces having identical polarity, due to Faraday’s Law Like-Charges Repel, in fact, they repel each other to the point that if the two parts are moving in opposite directions, the static charge of positive ions helps it along the way by utilizing the electromagnetic force, thus causing a “Maglev” phenomenon.

This restructuring of the “dipole surface” combined with the physical surface improvement of the metals, it helps reducing heat, friction and wear and returning efficiency and previously wasted energy back to the system for increased power and work.

Steel Shield lubricants with ABF Technology steps up oil flow, reduces metal film strength, improves the shear strength of the base lubricant, affects the overall reduction in friction and friction-related wear that is unsurpassed by any other product or process that is known to date.

The U.S. government in recognition of this excellent scientific contribution and to compliment Dr. George Fennell’s achievement they have named the street outside his first factory as Fennell Avenue.

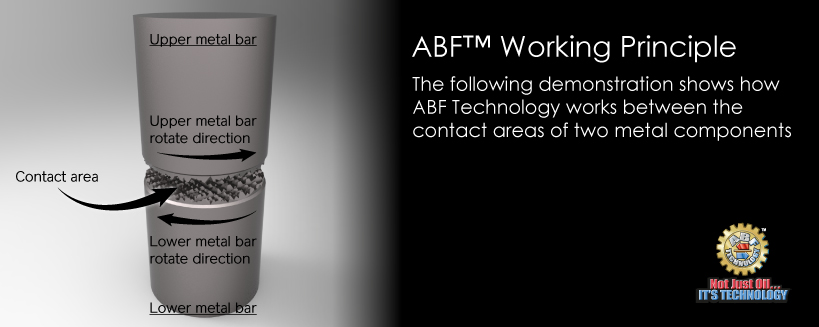

ABF WORKING PRINCIPLE

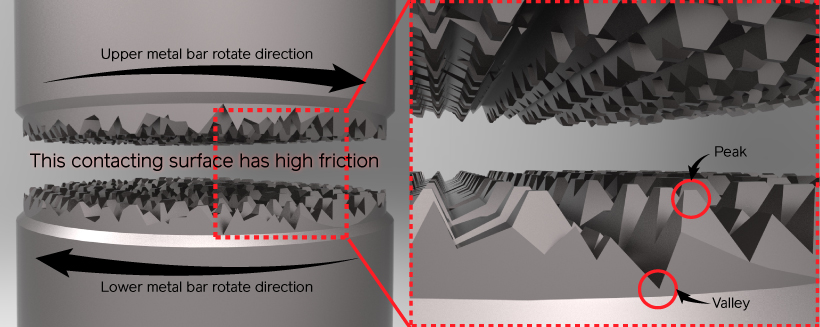

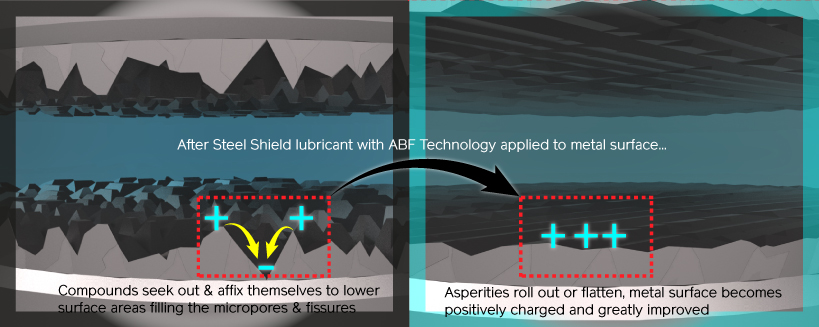

1. The Metal Surface

- Metal surface characterized by series of peaks and valleys

- Peaks (known as “asperities”) are positively charged

- Valleys (referred to as “micro-pores” and “fissures”) are negative charged

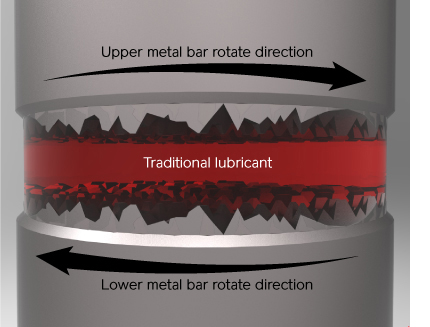

2. Traditional Lubricants

- Most lubricants help to slow the process of heat & friction to some degree

- When two metal surfaces contact each other & move in opposite directions, friction is caused, producing heat & metal deterioration

- Constant friction & electro-magnetic interaction causes the weakened metal to break off creating metallic debris & particles in the lubricant

3. Surface Treated With Advanced Boundary Film

- Forms electro-negative surface attaching compounds to seek out & affix themselves to lower surface areas filling the micro-pores & fissures

- Asperities roll out or flatten creating greatly improved metal surfaces

- Created in this process is a total positive state of polarity

- When metal surfaces become uniform in charge, there is a reduction in friction due to Faraday reaction of like-charges

Steel Shield Technologies' mechanism of operation is based upon advanced methods of Tribology that improve lubricity and load carrying capacity. This, in turn, improves surface characteristics while simultaneously creating a stable chemical Advanced Boundary Film on the contacting metal surfaces of whatever equipment of which it is added. The process of Advanced Boundary Film formation is achieved through a unique combination of long-chain halogenated hydrocarbons and other proprietary additives that are highly stable and non-corrosive to the equipment's metal parts, and pose no threat to the environment or waste oil recovery systems.

Steel Shield reacts chemically, under thermal conditions with the contacting metal surfaces, to form a complex surface attaching film of protection. Steel Shield's characteristics are "electro-negative", which causes it to seek out and affix itself to the metallic surface areas. During this process, surface smoothing is accomplished, resulting in improved spread characteristics of the surfaces themselves. The final state of the opposing metal surfaces increases the fluid film strength even more, resulting in greatly reduced wear while imparting extreme pressure (EP) properties to the opposing metal surfaces. The result is a virtual elimination of frictional wear and significant cooling of the entire lubricated area yielding higher energy savings and reduced metallic debris and acids in the oil. This is extensively proven through elemental oil analysis and Ferrography of the used oil, before and after the use of Steel Shield Advanced Boundary Film Technology.

STEEL SHIELD TREATS THE METAL, NOT THE OIL

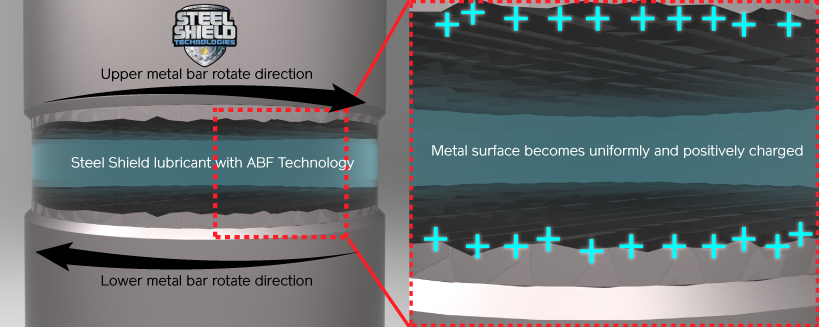

Close-Up Of Metal Surfaces As Demonstrated On Lubricant Tester

Steel Shield Technologies Inc. (USA) sole purpose is to manufacture premier quality metal treatments, additives, greases and lubricant oils that have been tested to exceed the normal parameters of extreme pressure and anti-wear products in the aftermarket, hereby offering matchless performance and unsurpassed protection against wear while saving maintenance costs, downtime, energy and improving overall functionality of your machineries. Steel Shield “Not Just Oil, It’s Technology” which makes a difference to the World of Lubrication. Steel Shield aims at helping customers to achieve the highest return on investment (ROI). Steel Shield is committed to strengthening business and global commerce through manufacturing and distributing, World-wide, the full line of ABF Technology products made in the USA, Singapore and Hong Kong.

Wearing of bearing cylinder without lubrication

Wearing of bearing cylinder with Steel Shield lubricant

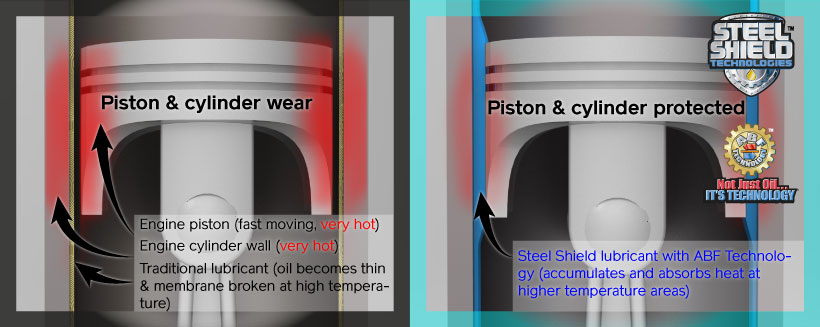

DYNAMIC HEAT TRANSFER

Protecting Metal From High Temperature

Engine runs hot with traditional lubricant

Engine stays cool with Steel Shield lubricant

Steel Shield ABF Technology – marked a new era in the world of lubrication!

- A bio-organic-chemical formula product

- Reduction of heat, friction and debris, especially significant

- Treats, rehardens and protects the metal surface

- Responsive, Powerful and Energy Saving

- Extends the life of your machine double and even more

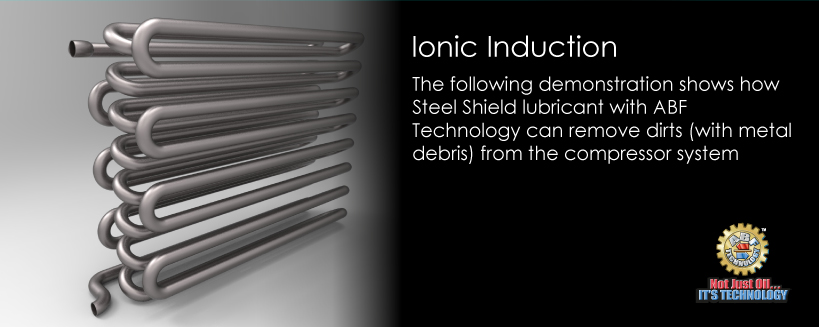

IONIC INDUCTION

Remove And Discharge Debris

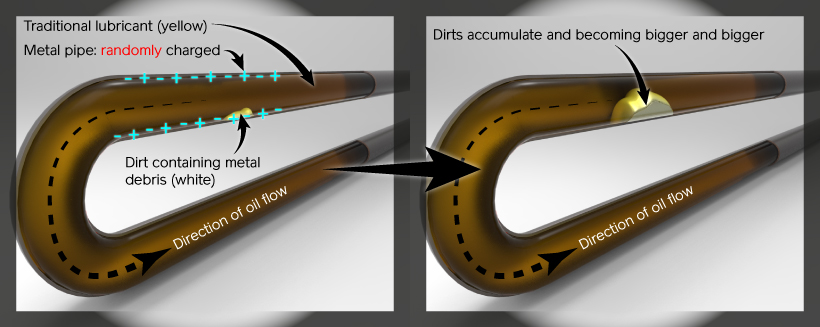

Traditional Lubricant

Compressor system with traditional lubricant

Dirts greatly reduce efficiency of the system

- Both metal pipes and dirts are randomly charged

- Traditional lubricants cannot stop the formation of dirts and debris

- Thus, dirts always become bigger and bigger inside metal pipes which greatly reduce efficiency of the compressor system

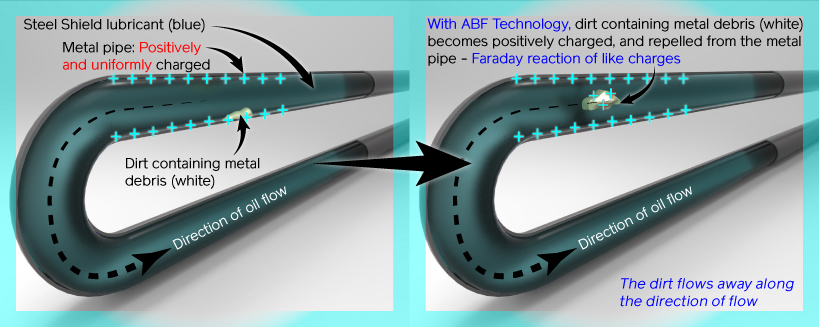

Steel Shield Lubricant With ABF Technology

Dirt (oil with metal debris) and pipe inner surface are positively charged

Dirt repelled (Faraday’s law) and detach from pipe surface, smooth oil flow means higher efficiency

- Both metal pipe and dirt (oil with metal debris) are positively and uniformly charged by Steel Shield lubricant with ABF Technology

- Dirt are being repelled and detach from the metal pipe surface due to Faraday reaction of Like-Charge

- Dirt flows away along the direction of lubricant flow

- Thus, the efficiency of the compressor system greatly enhanced