STEEL SHIELD MILITARY INTRODUCTION

Improving Functional Reliability Of Weapons

How Weapon Shield Works?

Weapon Shield CLP, Weapon Shield Solvent and Weapon Shield Grease are all petrochemical products specially formulated for use in today’s weaponry and for the sport industries. With the addition of Weapon Shield CLP, Weapon Shield Solvent and Weapon Shield Grease dramatically increase lubricity between metal surfaces and moving metal parts, and thus reduce frictional heat and wear exponentially.

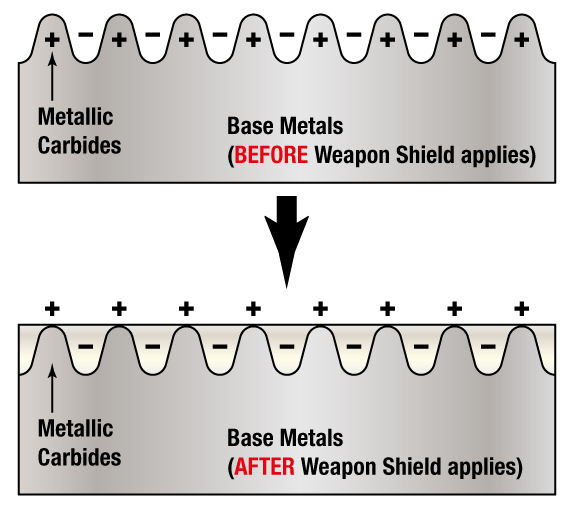

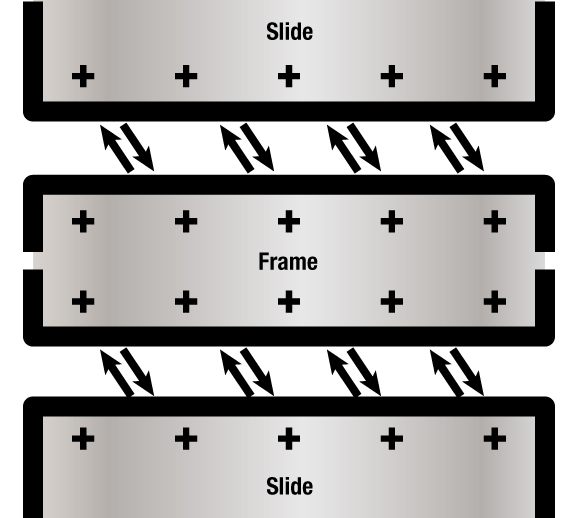

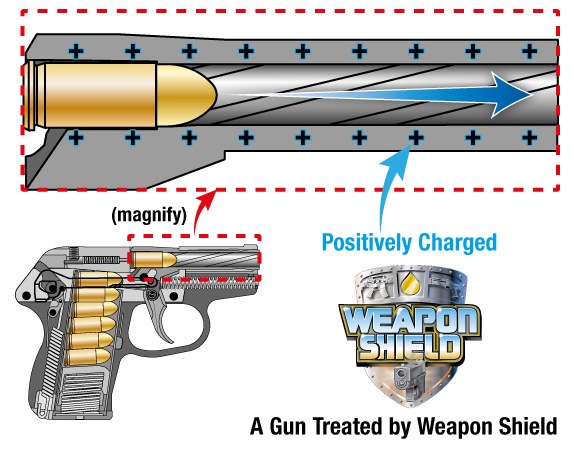

When these Steel Shield products are applied to a system, such as the moving parts or slide of an auto (below), there is a cation exchange of ions which fills up the low surface areas of the metal and alters the surface to create a totally positive state of polarity. When the metal surface polarity becomes uniform in charge, there is a reduction in friction due to the Faraday reaction of like charges. Likewise, in the case of Weapon Shield, a similar reaction takes place within the bore is the treated static metals of the rifled lands assist in ballistic movement of the bullet due to reduced frictional coefficients. This causes a more even build of pressure during ignition due to the fact that the bullet sees less frictional resistance from the lands, causing an improved accuracy expressed in better average velocities, extreme spreads, standard deviations, and bullet groupings.

Letters From US Army In Iraq And Afghanistan:

Steel Shield Technologies (SST) is one of the leading manufacturers of advanced specialty lubricants, additives and greases. Our products include greases, spray lubricants, cutting oils, automotive lubricants and specialty additives specifically designed for Military applications. Please don’t hesitate to check out the following customers’ reference letters:

Technical Papers:

WEAPON SHIELD, Lubricant, Cleaner, and Preservative for weapons and weapon systems, has proven to be the superior product of its kind to improve functional reliability and dependability of firearms even under hostile heat and adverse environmental conditions. Most feeding and extraction problems (jams) of semiautomatic and full-automatic operation are evolved from three sources:

- Excessive heat from repetitive fire

- Burnt powder accumulation through firing, and

- Hostile environmental conditions such as dirt and sand

WEAPON SHIELD will address and protect against all three conditions from influencing the proper functioning of the weapon. Here's how...

Dysfunction Due To High Heat

Many semiautomatic and full-automatic weapons will dysfunction after periods of fire sufficient to build up and transfer high heat to the receiver and its moving parts. This is caused by the intense heat changing the fine tolerances of the weapon through swelling and the vaporization of existing lubricants in critical areas of operation. These two factors will cause an increase in the frictional coefficients involving the slides, bolt carriers, and other moving parts. When this occurs, the spring forces, originally engineered to function under proper conditions, become stressed and will not exert the increased force needed to eject the spent casing and retrieve a new round from the magazine while delivering the bolt carrier to its full battery position. WEAPON SHIELD TM will in every case, permeate the metal surfaces of all moving parts to which it is applied and dramatically increase the lubricity by a factor of 50:1 over conventional lubes and other CLPs. Even if WEAPON SHIELD appears to "vapor off" under intense heat, the boundary film layer created by WEAPON SHIELD will still be present and continue to provide lubricity and low coefficient of friction operation. Two examples are Heckler & Koch's MP-5 submachine gun and Barrett Firearms' M92A1.50 caliber semiautomatic. Both models have a tendency to dysfunction after sufficient heat is generated through firing while using conventional lubricants. If WEAPON SHIELD is applied, no dysfunctions associated with lubricity and tolerance change will occur. Feeding and extraction problems in the Remington 870 shotguns will also be rectified from the use of WEAPON SHIELD.

Reliability is our first concern...

there is no room for weapon dysfunction when officers and soldiers lives are on the line.

This problem is very straight forward and can be equated to rather immediately, especially in high volume semi and full automatic fire where rapid generation of powder fouling is more evident that the norm. If WEAPON SHIELD is used as the cleaning, lubricating, and protecting product for the particular weapon, burnt powder and fouling will be rejected from the surfaces of the weapon due to WEAPON SHIELD's chemical ability to create an electrochemical boundary film that will reject positive(+) ions of burnt powder generated during the ignition process. This is also true and functional for hostile environments of dust and sand. All airborne particulates achieve a positively(+) charged electrostatic state and are attracted to objects that exhibit a more negative(-) charge (ground). For this reason, dirt and dust collect on walls and other vertical surfaces producing grit and grime. WEAPON SHIELD will create an electrochemical positive(+) surface which will reject positively charged particles. (Faradays law - like charges repel; unlike charges attract.) Please note that an excessive amount of oil of any kind will tend to attract dirt so use WEAPON SHIELD in a modest-to-light application.

LEAD Removal And Copper Build-Up Prevention With Weapon Shield

WEAPON SHIELD will remove burnt powder and lead better than any non-corrosive product in the marketplace. A thorough swabbing of the chamber and bore with a wet patch containing WEAPON SHIELD and allowed to sit and work briefly will remove all powder and leading. In severe cases of lead build-up, WEAPON SHIELD should be left in the bore from 2 hours to overnight. This allows the WEAPON SHIELD to work through and tunnel under severe accumulations, entirely removing the build-up from the bore and chamber. WEAPON SHIELD is non-acidic and is a neutral pH-7 and works by creating a surface charged boundary film described in the previous section. This same effect will prevent the accumulation or build-up of copper and gilded metals from jacketed bullets if WEAPON SHIELD is used on a regular basis to clean, lubricate, and protect the weapon.

Stainless Steel Weapons And Weapon Shield

When WEAPON SHIELD is used on all, or partial stainless steel weapons, dysfunction, along with galling is eliminated. No other product can equal or outperform WEAPON SHIELD when lubricating and protecting stainless steels. All weapons will significantly benefit from the use of WEAPON SHIELD in their operation, functional reliability, resistance to fouling, and extended service life due to decreased wear through dramatically improved lubricity and reduced friction.

PROTECT from Saltwater Contamination

The ultimate tool in the total care and maintenance of all tough tackle in both on shore and seawater equipment. Steel Shield products have been especially tested in harsh saltwater conditions and proved to be superior in its performance