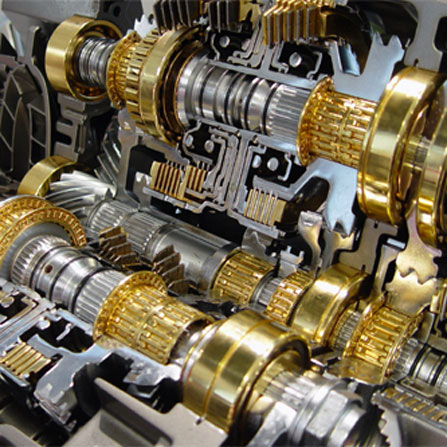

AUTOMOTIVE GEARS LUBRICATION

Steel Shield Automotive Gears Lubricants are the ultimate protector and energy saver for any gearing system. Gear contacting faces and bearings are treated by unique ABF Technology which enhance the surface hardness and smoothness. The result are: gears last much much longer and energy consumption drop to the minimum. Steel Shield lubricants DO NOT contain any solid additives which can damage your precious gears, because ABF Technology is more advanced than most of the premium lubricants in the market.

Automotive Gear Lubricants

The following inducates the general applications of automotive gears which includes all the spur, helical, spiral bevel, hypoid and planetary gear types:

- Automotive Transmissions

- Light Duty: Cars and light trucks

- Heavy Duty: Commercial trucks, e.g. Allison

- Power Transmissions: e.g. Caterpillar, Clark

- Manual Transmissions

- Light Duty: Synchronized

- Heavy Duty: Mainly non-synchronized

- Transaxles: Front wheel drive vehicles

- Transfer Cases: Four wheel drive vehicles

- Differentials: Hypoid gears

- Final Drives: Planetary gears

- Tractor / Wet Brake Applications

| The 6 General Automotive Lubricant Types And Applications | ||

|---|---|---|

| Lubricant | Applications | |

| 1 | Automatic Transmission Fluid (ATF) | Automatic transmissions and some transfer cases |

| 2 | Non Extreme Pressure (R&O) Gear Oil | Heavy duty manual transmissions |

| 3 | Full Extreme Pressure (EP) Gear Oil | Differentials, final drives, transfer cases & manual transmissions |

| 4 | Engine Oils | Manual transmissions |

| 5 | CAT TO-4 Fluids | Caterpillar transmissions and hydraulics |

| CAT FDAO Fluids | Off-highway Caterpillar final drive, differentials and axle components | |

| 6 | Universal Tractor Fluids | Common sump (transmissions, wet brake and hydraulics) of agricultural tractors |

API Service Designation

The API Gear Lubricant "GL" designation classify automotive gear lubricants which relates to the automotive gear service. Notice that the GL designations do not included all the automotive gear appications mentioned above and no performance tests are carried out to classisfy the lubricants. Notice that GL-5 lubricants have much higher concentration of extreme pressure (EP) additive than a typical industrial EP gear oil (upwards of 4 times). So, industrial gear lubricants cannot be used in automotive applications. Also, limited slip differentials require a special additive to be present in the lubricant. Conventional GL-5 gear lubricants can only be used to top-up (not refill) limited slip differentials. Here is the short list of API designations:

| API GL Designations Not In Current Use | |

|---|---|

| Designation | Applications |

| API GL-1 |

|

| API GL-2 |

|

| API GL-3 |

|

| API GL-6 |

|

| API GL Designations Currently Using | |

|---|---|

| Designation | Applications |

| API GL-4 |

|

| API GL-5 |

|

API Service Designation Beyond GL

API GL designations do not included all the automotive gear applications. Several heavy truck manufacturers defined their own specifications (e.g. Allison C-4, Caterpiller TO-4, and TO-2, Mack TO-A. etc.). These may require special lubricants or may be met by (non-EP) diesel engine oils (e.g. CJ-4) or ATFs. Here reviewed some examples of designations:

| API Designations Beyond GL | |

|---|---|

| Designation | Applications |

| API MT-1 |

|

| MIL-PRF-2105E |

|

| SAE J2360 |

|

API Service Designation Summary

Always check the owner's manuals for automatic transmission lubricant recommendations and consult the manufacturers when necessary.

| Lubricants And Designations Summary | |

|---|---|

| Designation | Applications |

| Automatic Transmission Fluid (ATF) | Generally meets D3M and C-4 and TO-2, or Mercon V®, or Dexron VI®, or Mopar ATF+4® |

| Non Extreme Pressure (R&O) Gear Oil | Generally GL-1 and MIL 2104 |

| Full Extreme Pressure (EP) Gear Oil | Generally GL-5, GL-4, MIL-PRF-2105E, Mack GO-J, and MT-1 |

| Engine Oils | Generally CJ-4, SM, TO-2, C-4 |

| CAT TO-4 Fluids | TO-4, TO-2 and GL-3 |

| Universal Tractor Fluids | Generally TO-2, John Deere J20C (summer) and J20D (winter), and New Holland FNH 200 (all season) |

SAE Viscosity Grade Classifications For Automotive Gear Oils

The SAE viscosity grades are based on the lubricant viscosity measurements at both high and low temperatures. The high temperature (100℃) kinematic viscosities tests can ensure the mechanical components have adequate lubricant film thickness in order to prevent wearings. The low temperature (-12℃, -26℃, -40℃ and -55℃) viscosities measures by the Brookfield tests ensure there is enough lubricant flowability to avoid components damage in low temperature cold-start conditions.

| SAE J306 Automotive Gear Lubricant Classification (200506) | |||

|---|---|---|---|

| SAE Viscosity Grade | Max Temperature for Viscosity of 150,000 cP(℃)(1,2) | Kinematic Viscosity at 100℃ (cSt)(3) | |

| Min(4) | Max | ||

| 70W | -55(5) | 4.1 | |

| 75W | -40 | 4.1 | |

| 80W | -26 | 7.0 | |

| 85W | -12 | 11 | |

| 80 | 7.0 | <11 | |

| 85 | 11 | <13.5 | |

| 90 | 13.5 | <18.5 | |

| 110 | 18.5 | <24.0 | |

| 140 | 24 | <32.5 | |

| 190 | 32.5 | <41.0 | |

| 250 | 41.0 | ||

|

Note:

|

|||

.jpg)