GEARS LUBRICATION INTRODUCTION

Steel Shield Gears Lubricants are the ultimate protector and energy saver for any gearing system. Gear contacting faces and bearings are treated by unique ABF Technology which enhance the surface hardness and smoothness. The result are: gears last much much longer and energy loss drop to the minimum. Steel Shield lubricants DO NOT contain any solid additives such as molybdenum which can damage your precious gears, because ABF Technology utilizes ionic-maglev mechanism which is more advanced than the fluid & gaseous lubrication mechanism adopted by most of the premium lubricants in the market.

Enclosed Gears Of Automotive And Industrial Systems Classifications And Additives

Mechanical energy is transmitted through the meshing gear teeth from the motor drive or other power source. The teeth must be kept apart and protected from excessive wear by a thin lubricant film. The gear systems usually operate in an elastohydrodynamic (EHD) lubrication regime. Generally, every gearbox has bearings on the ends of the spinnning shafts, and they must be lubricated by the same lubricant. Also, in order to select the best gear lubricant, the oil types, additives, and the viscosity gtrade must be considered for the target gear types, speed, load, ambient air temperature and oil operating temperature. The major functions of the lubricants are as follows:

- To lubricate and separate the metal parts

- Cool down the gear system

- Prevent rust and corrosion

- To control temperature

- Help to control and reduce contamination through filtrations

Fig.1: Spur Gear

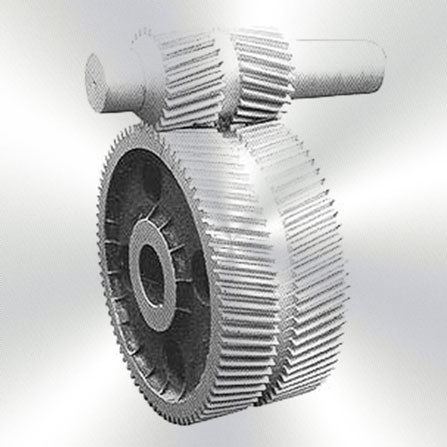

Fig.2: Helical Gear

Fig.3: Herringbone Gear

Fig.4: Planetary Gear

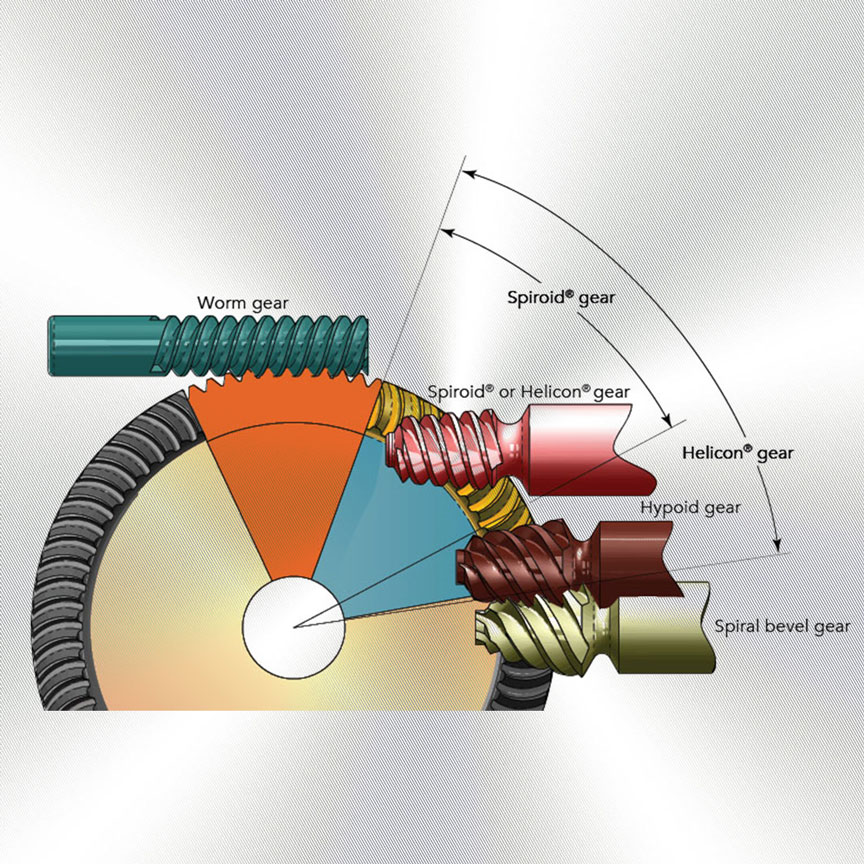

All of the gear sets in the top row have input and output shafts which are parallel to each other. The gear sets in the bottom picture (Fig.5: Spur Bevel, Spiral Bevel, Hypoid Gear and Worm Gear) have shafts which are perpendicular to each other which are always more difficult to lubricate because the sliding friction between the teeth have increased.

Steel Shield gear lubricants utilize ABF Technology which can greatly reduce any gear damage problems due to fatigue, wears, corrosion, plastic deformation, fracture, erosions, cavitiation, and much more.

.jpg)