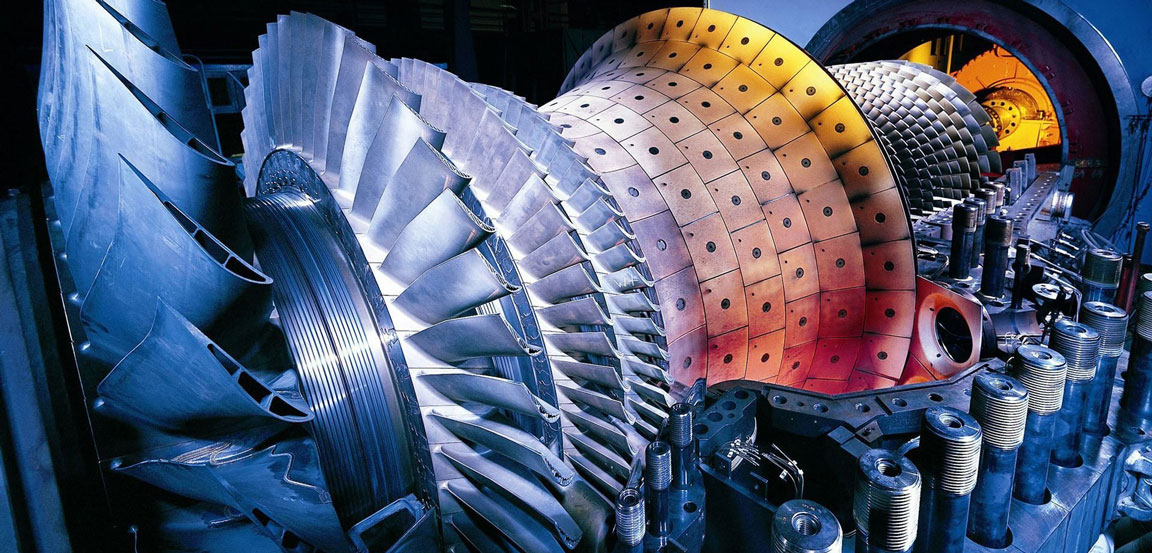

STEEL SHIELD GAS ENGINE LUBRICANTS

Excellent Metals Protection Formula Results In Extended Service Life And Ultra High Efficiency

Gas Engines like Natural gas engines (NGE) and Bio-Gas Engines are commonly used to power gas compressors, stationary electric generators, fire water and irrigation pumps. They can generate electricity in primary cogeneration electrical power plants. Natural gas engines have lower exhaust emissions of nitrogen oxides (NOx), carbon monoxide (CO), particulates and lower fuel costs than diesel engines. Compare with diesel and gasoline engines, natural gas engine have the following different properties:

- Burn cleaner, with no soot contamination of the crankcase engine oil, and thus lower detergency/dispersancy additives and ash contents are required.

- Burn gaseous fuel and no fuel dilution. Therefore, prevent the lubricant viscosity from increase is more important

- Burn hotter than diesel engines (165°C to 235°C/300°F to 400°F higher exhaust temperature). Valve wears increase as oxidation and nitration of oils occur more severely

- Operate at constant speed. Gas engines are trend to retaining deposits and plug fouling

The ash is the portion of the lubricant that is left behind as a deposit after complete burning of the oil. It is white-gray in color and comes from the metallic detergents (calcium and barium) and antiwear (zinc) additives of lubricants. Reflecting the various needs of the different engines, premium gas engine oils can be classified as follows:

- Ashless (less than 0.1 percent sulphated ash)

- Low ash (0.2 to 0.6 percent)

- Medium ash (0.7 to 1.2 percent)

- High ash (greater than 2.0 percent)

Ash contents can protect valves in four-stroke engines. The detergent additives (which are bases) neutralize acids. Lubricants with the lowest ash content is optimal to provide balanced valves protection and acid neutralization. Higher ash contents of the oils can lead to higher accumulation of deposits in the engine. Using oils with ash content higher than necessary, overlubrication can result in high deposits contents, and lead to reduction in heat transfer, preignition and/or detonation, ring sticking or breaking, plug fouling and valve burning.

Steel Shield Gas Engine Lubricants have unique ABF Technologies and high quality base oils which provide the best metal lubrications and protections, and well balanced ash contents for you precious engines. Please click the following products to see more detail specifications:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)