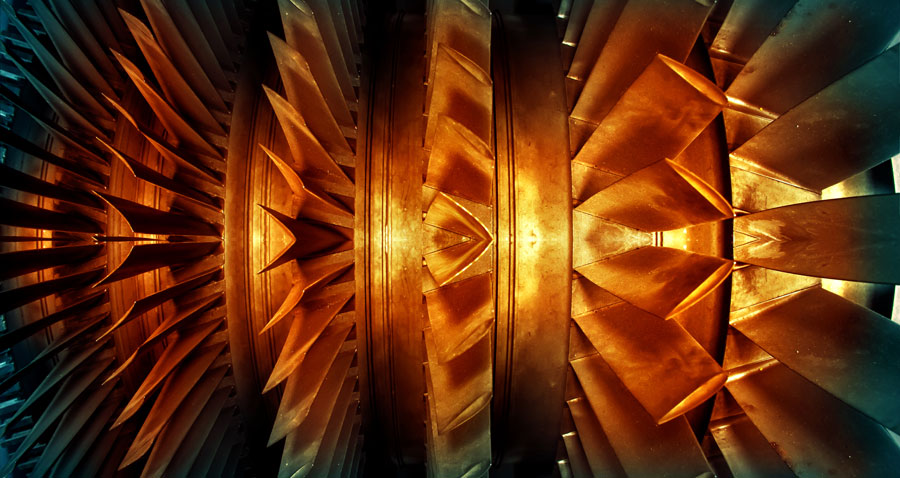

STEEL SHIELD TURBINE LUBRICANTS

All Round Lubricants Providing High Engine Efficiency, Long Service Life, Reduction In Energy And Maintenance Costs

Dramatically Enhance The Service Of The Turbine System

Steel Shield Turbine Lubricants can highly reduce wear, friction, keep systems clean and cool, and prevent rust and corrosions. With ABF Technology, plain and rolling element bearings, thrust bearings, gears, couplings, and contact type seals become ultra-smooth and long life. The overwhelming majority of hydroelectric plants require extremely reliable and long life operating services. These are the reasons Steel Shield Turbine Lubricants with ABF Technologies should be used. Steel Shield Turbine Oils have excellent premium anti-rust, anti-oxidation, water-separating and air separation characteristics. In order to suit a wide range of bearing designs, speeds, and operating temperature, Steel Shield Turbine Oils cover ISO visocsity grades of 32, 46, 68 and 100 which are adequate for the plant's operations. The lubricants have amazing cold start properties which have adequate fluidity for proper circulation at temperatures below freezing points. Steel Shield's ABF Technology with enhanced metal treatment technology are be desirable to provide additional protection during starting and stopping of turbine system. Air separation characteristics of the oils ensure that air picked up in the accumulators separates readily in the reservoir.

STEEL SHIELD TURBINE LUBRICANTS are suitable for all types of steam turbines, gas trubine, hydro turbines and aero-serivative gas turbines without any undesirable effects which damage the metals. Also, Steel Shield lubricants DO NOT contain any solid additives. It utilizes ABF Technology which treats the metal, not the oil.

.jpg)